Injection

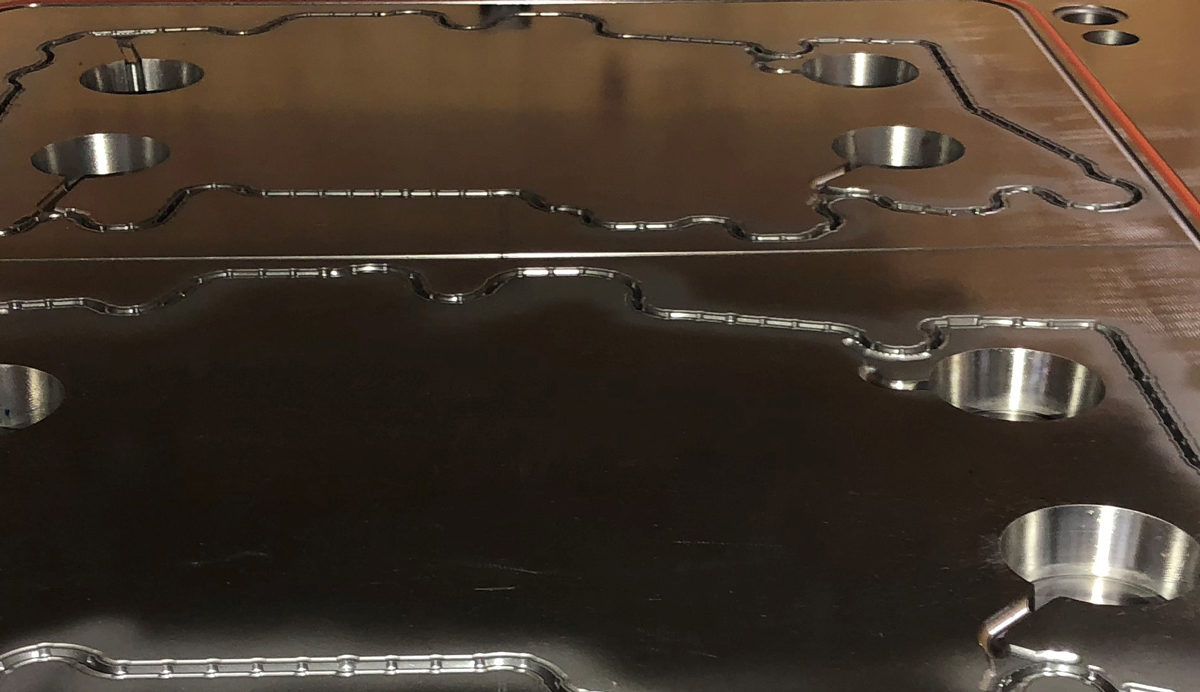

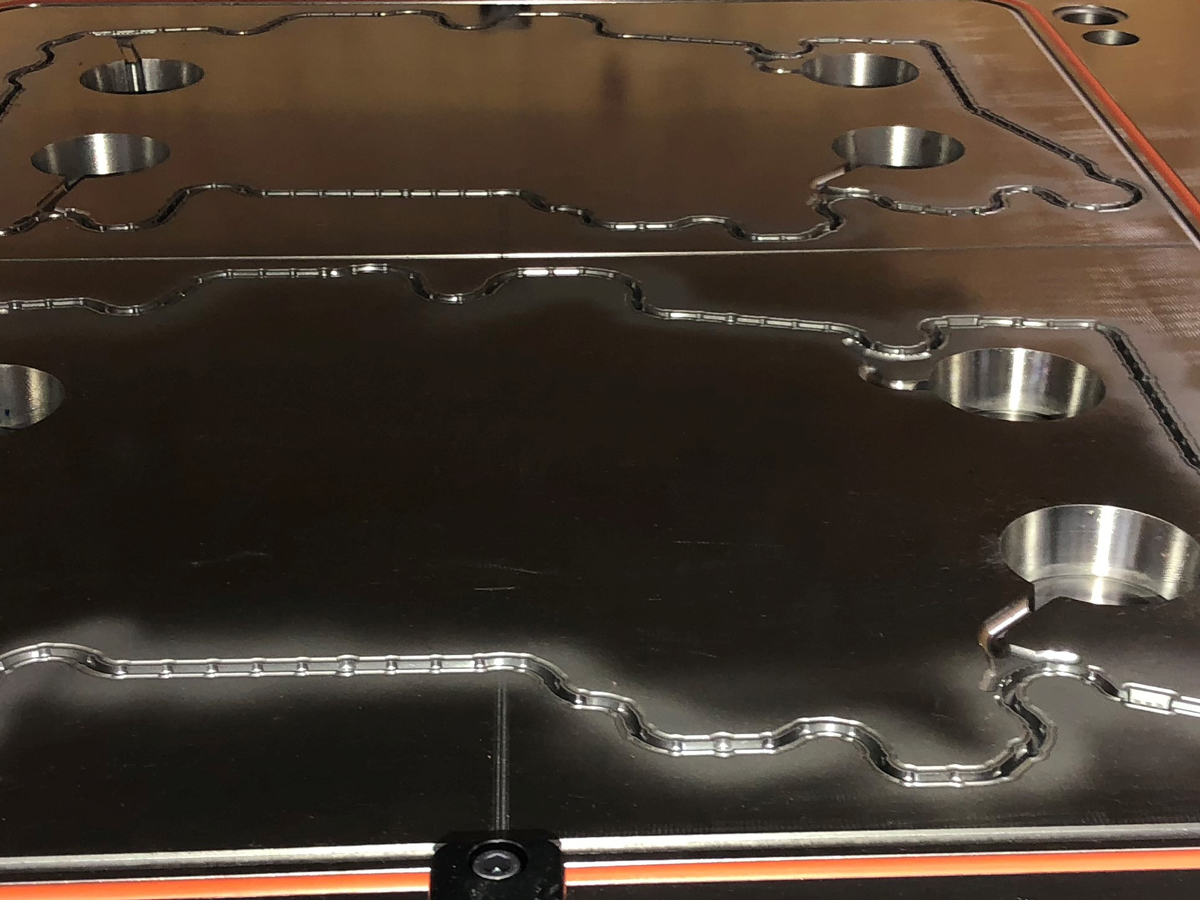

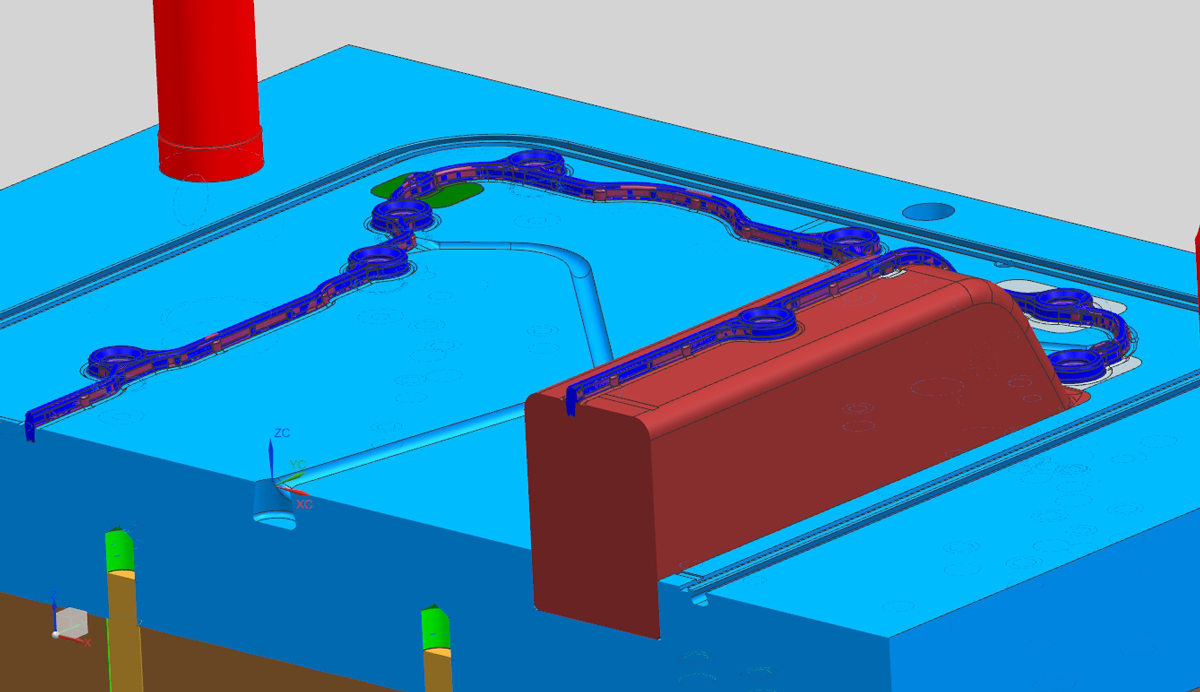

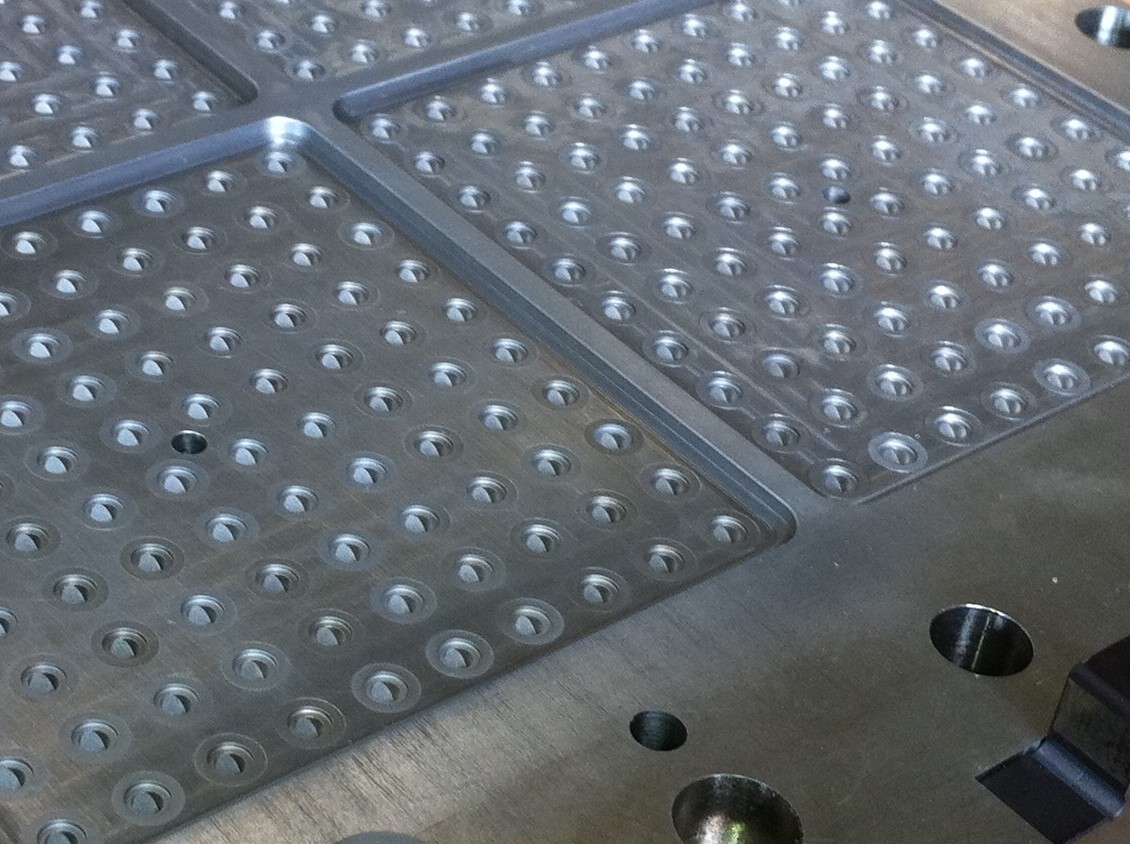

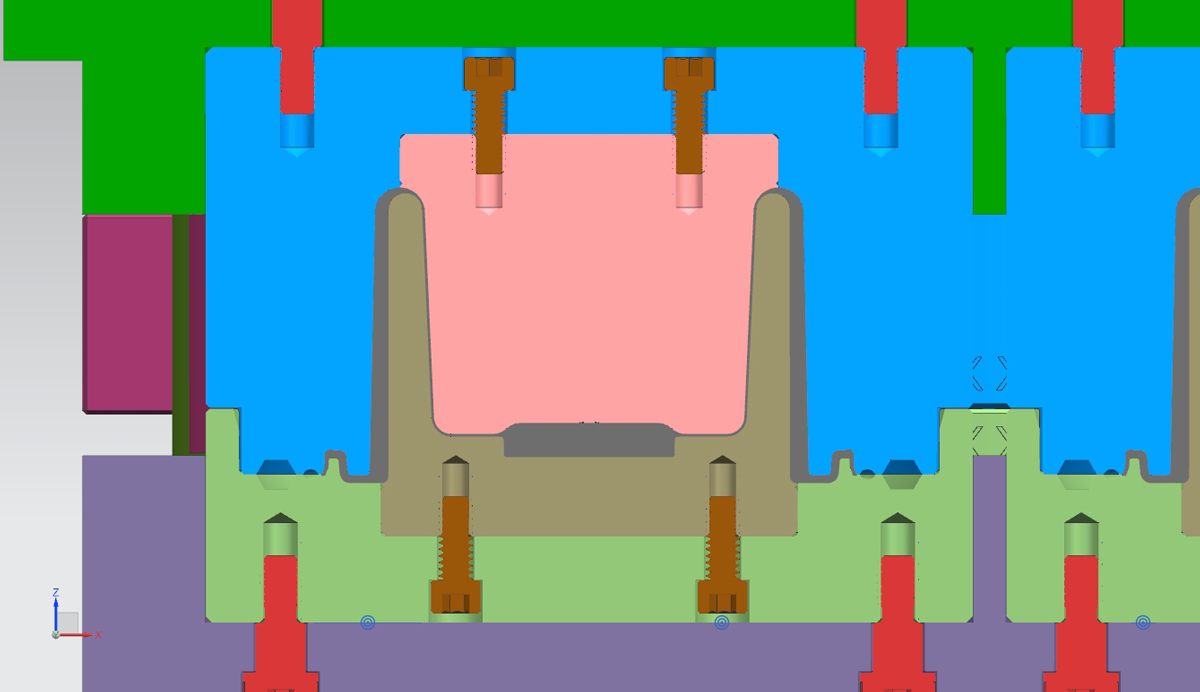

Injection molding allows for preheating/plasticizing of the material prior to delivery into the hot mold. This reduces cycle times and aids in processing and consistency. Material delivery can be accomplished thru a traditional runner system (hot runner), or thru a valve-gated or open-nozzle cold runner. Cold runner systems reduce waste and improve cycle times by reducing mold service time or allowing for automation to service the mold more easily. These systems use proven technology that can be applied effectively in today’s high-tech manufacturing operations.

Injection molding allows for preheating/plasticizing of the material prior to delivery into the hot mold. This reduces cycle times and aids in processing and consistency. Material delivery can be accomplished thru a traditional runner system (hot runner), or thru a valve-gated or open-nozzle cold runner. Cold runner systems reduce waste and improve cycle times by reducing mold service time or allowing for automation to service the mold more easily. These systems use proven technology that can be applied effectively in today’s high-tech manufacturing operations.