Compression

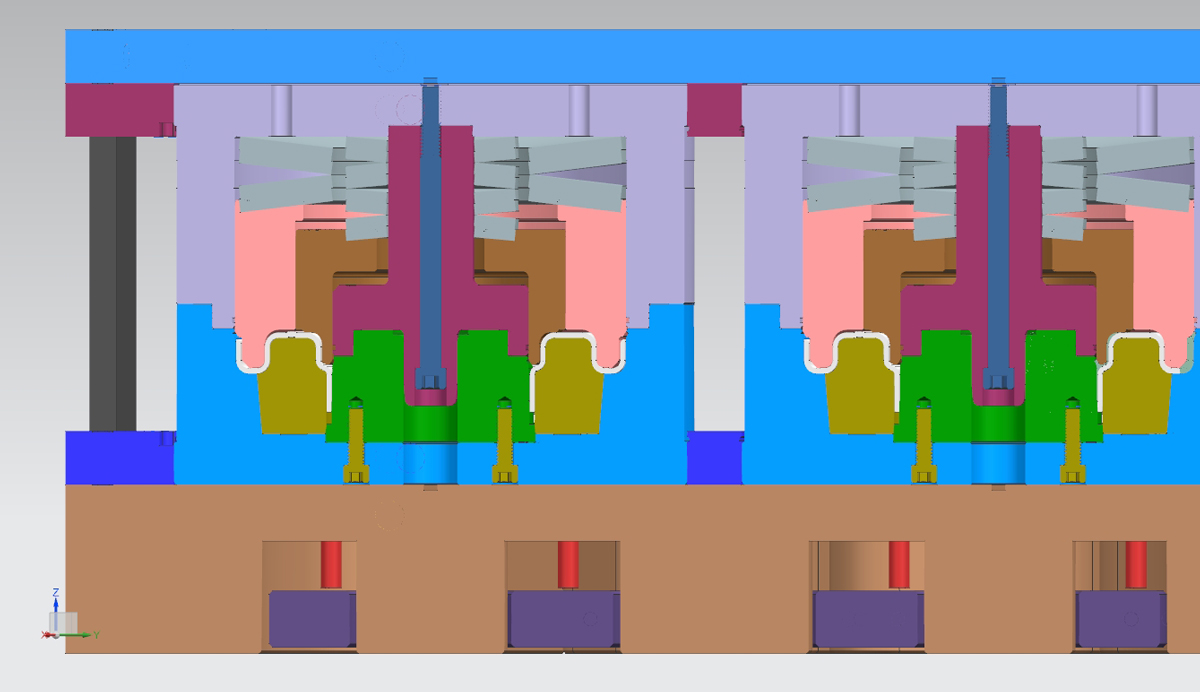

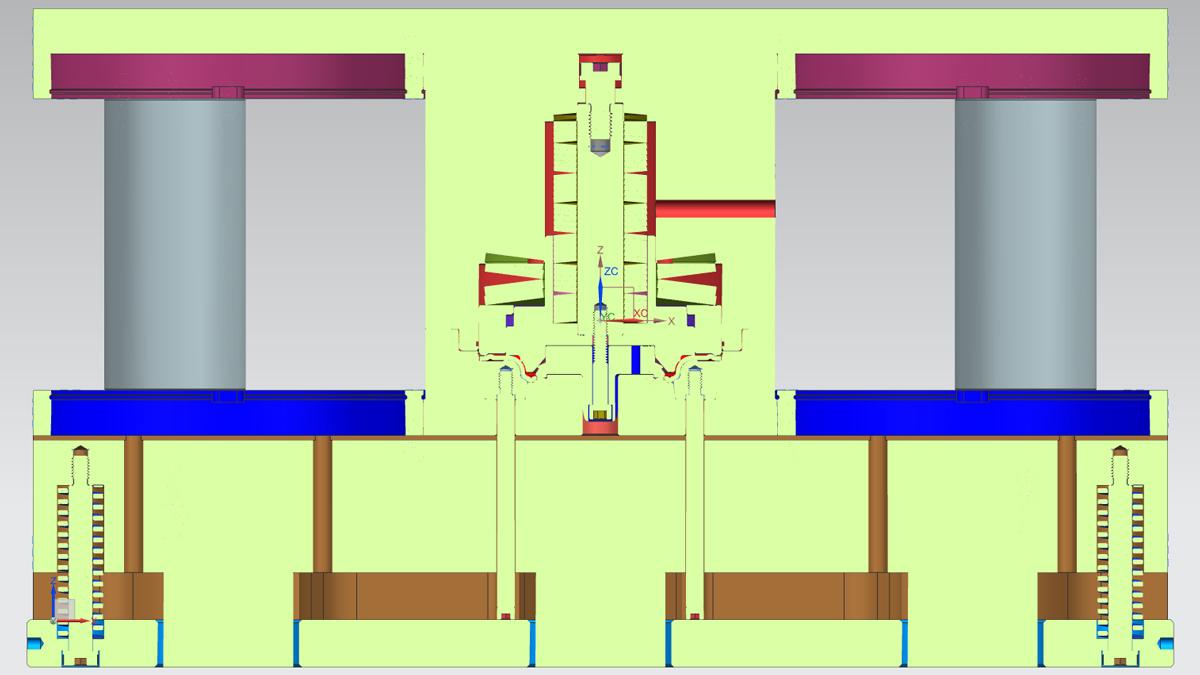

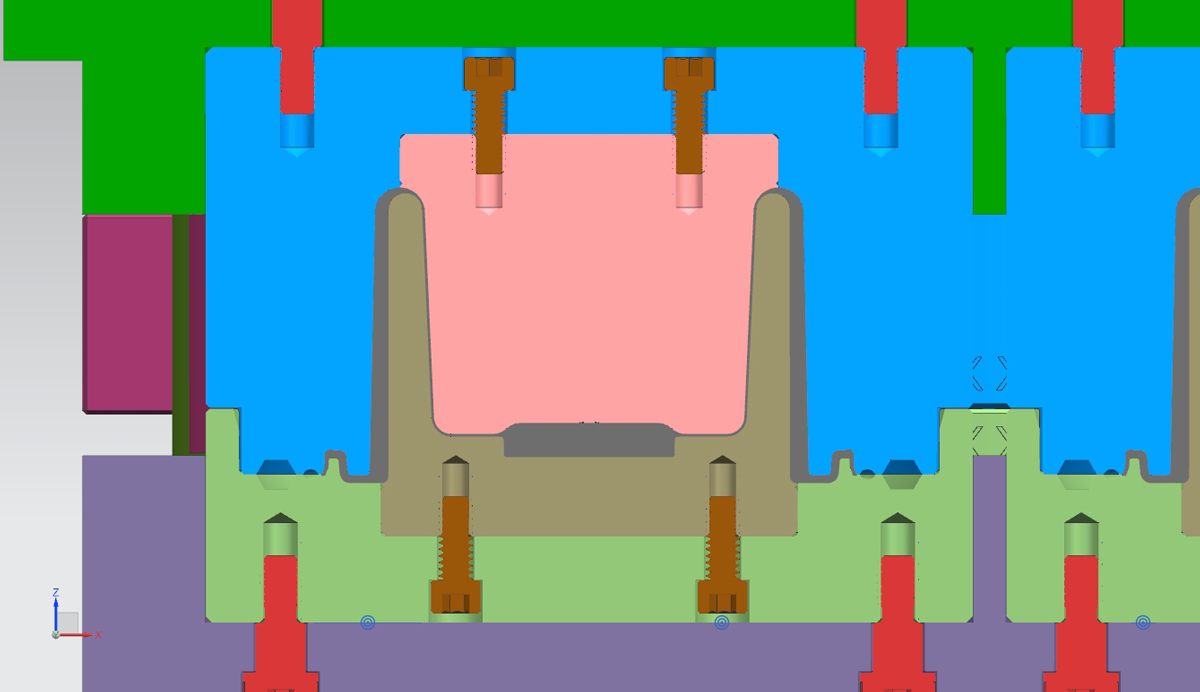

As an ‘open mold’ process, compression is often considered the most simple process from a tooling perspective. In many cases, a compression process can yield very low levels of material waste – – but often at the expense of requiring secondary trimming or finishing processes. We can build simple 2-plate compression molds, or complex multi-cavity precision compression tools with pre-clamp features and provisions to control flash when overmolding onto a metal insert.

As an ‘open mold’ process, compression is often considered the most simple process from a tooling perspective. In many cases, a compression process can yield very low levels of material waste – – but often at the expense of requiring secondary trimming or finishing processes. We can build simple 2-plate compression molds, or complex multi-cavity precision compression tools with pre-clamp features and provisions to control flash when overmolding onto a metal insert.