Liquid Silicone Rubber Molds

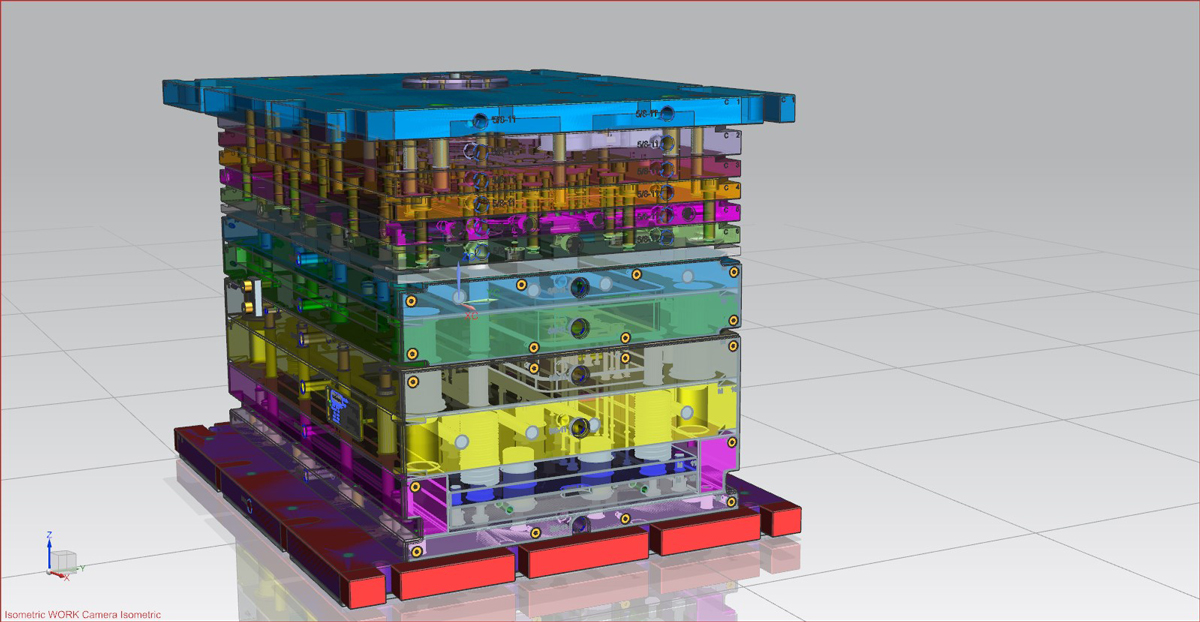

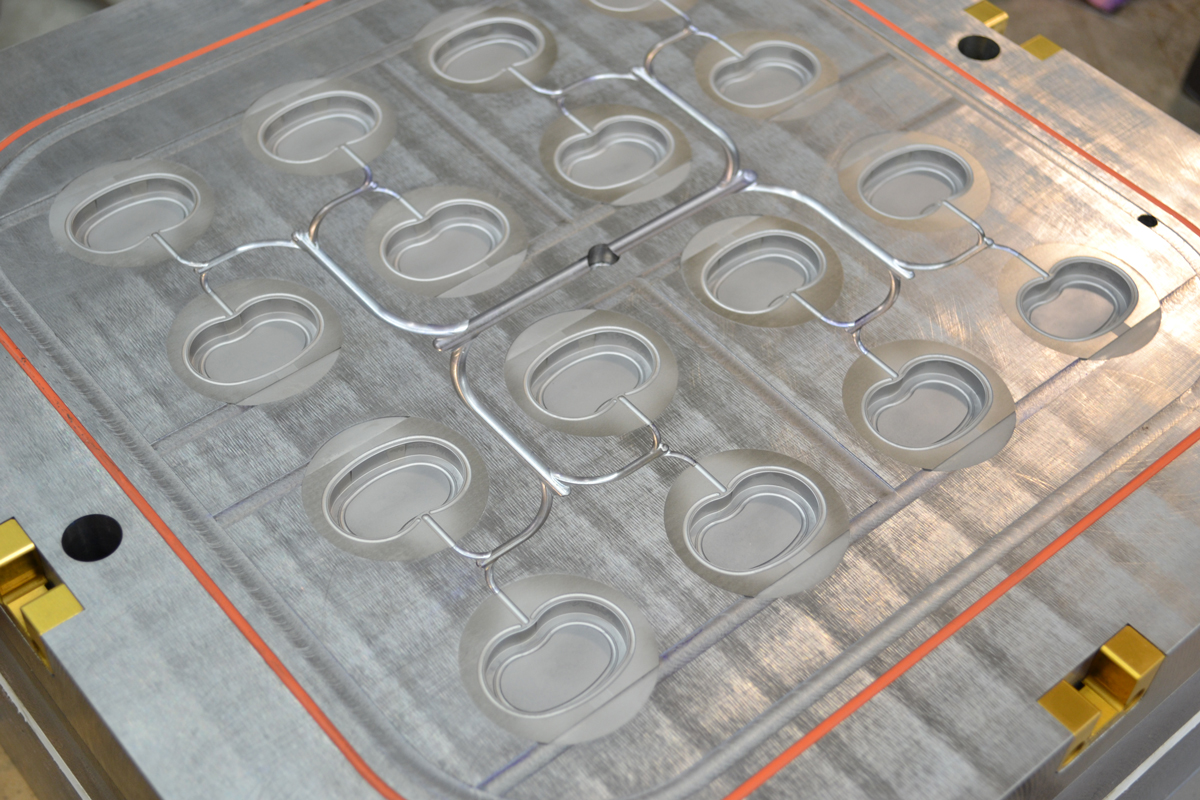

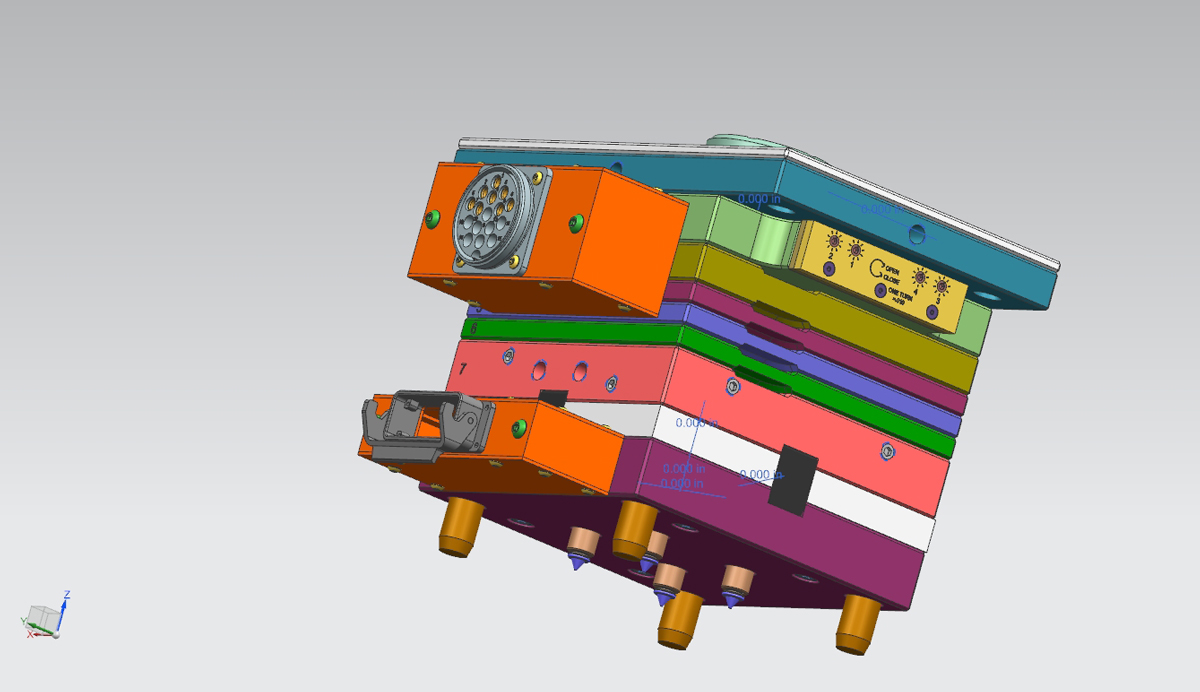

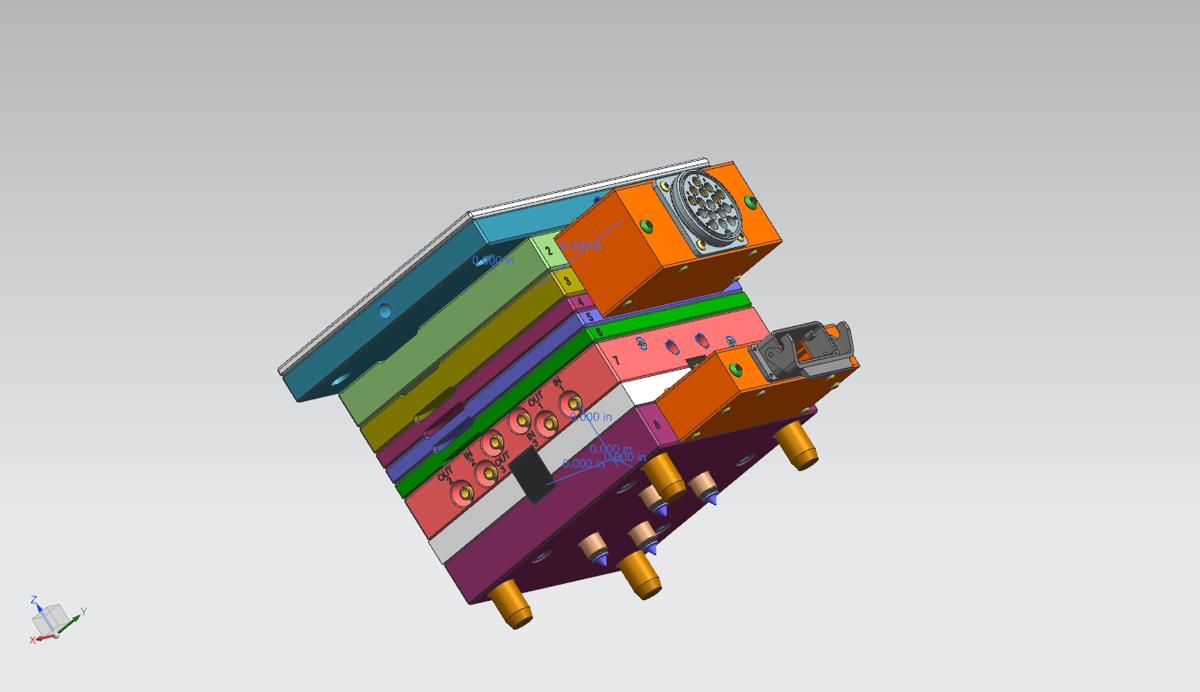

LSR is certainly one of the largest growth areas in the elastomer industry as material science and properties continue to evolve. Offering much faster cure times than most typical elastomers, LSR requires that the mold-builder and processor understand specific mold design methods to control flash and prevent leakage into unintended areas. LSR molds frequently utilize a valve-gated cold runner to minimize waste and control drool, and these systems aid in automating production for the fastest possible cycle times. End-of-arm tooling is frequently used for de-molding and automation. We can assist with a wide range of projects from prototype to production tooling.

LSR is certainly one of the largest growth areas in the elastomer industry as material science and properties continue to evolve. Offering much faster cure times than most typical elastomers, LSR requires that the mold-builder and processor understand specific mold design methods to control flash and prevent leakage into unintended areas. LSR molds frequently utilize a valve-gated cold runner to minimize waste and control drool, and these systems aid in automating production for the fastest possible cycle times. End-of-arm tooling is frequently used for de-molding and automation. We can assist with a wide range of projects from prototype to production tooling.